The earth system is large and heterogeneous, making it extremely challenging to characterize and understand. Our work uses a foundation in sensors, signal processing, data science, and online controls to address challenges being met by scientists, regulators, and industry. Projects range from measurement of water chemistry to development of novel data fusion algorithms, however every initiative is aimed at enabling critical environmental measurements in the field and in real time, coupled with use of this information in closed-loop controls, early warning systems, or adaptive human-directed field sampling campaigns.

This lab was also a key leader in the 2018 Multimodal Data Fusion Workshop – aimed at bringing together the broad community leveraging application-specific data to support approach-level innovation that can underpin improved solution delivery across all sectors and disciplines. (Workshop report and related publications available on the publication page.)

Integrated In-situ Sensing Systems

Making chemical measurements in the environment at high spatial and/or temporal resolution requires addressing a number of challenges, including:

(1) development of field-transportable sensors/instruments,

(2) deployment of a large number of fixed-location sensors or

a limited number of sensors aboard a mobile platform, and

(3) communication of data to a centralized database, preferably

in real time.

Our lab frequently partners with other researchers using remotely- and autonomously- operated vehicles to enable such studies.

Extending Machine Learning Approaches – “Teaching” them Environmental Chemistry

The concentrations of major ions in natural waters profoundly influence ecosystem structure and affect the suitability of waters for human use; furthermore, ion concentrations – and relative proportions – can often be used as a “fingerprint” of water (and thus potentially pollution) sources. Despite this, the high costs of grab sampling campaigns and laboratory analysis mean that even these relatively common constituents of water are measured only infrequently and typically at low spatiotemporal resolution – substantially reducing their utility for diagnosis or remediation of threats to ecosystems.

In response to this disconnect, we are developing a relatively low-cost field portable system for measurement of the full suite of major ionic water constituents (as well as some important ionic nutrient species) with data to be provided to the user in real time, i.e., sampling time of <5 minutes. This instrument will create the ability to lead high-resolution, adaptive studies, resulting in more precise identification of problems and better-targeted follow-on efforts in natural waters, while simultaneously offsetting the current prohibitively high campaign costs. This instrument has been validated in the lab and is currently being packaged for field use to enable field testing.

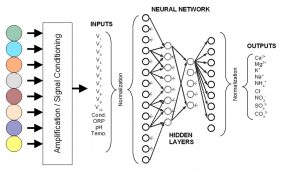

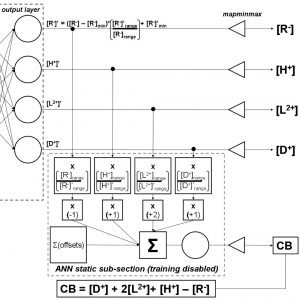

This multi-sensor instrument is designed around affordable ($200/probe) but imperfectly-specific ion selective electrodes (ISEs) which are commercially available for many (but not all) ions of interest and have proven useful under controlled lab conditions and protocols. Rather than focus on improvement of the sensors themselves or replication of lab techniques in the field, a combined architecture was pursued wherein novel signal processing architectures were explored for overcoming the sensor interferences and non-linearities experienced in in-situ conditions. Artificial intelligence and machine learning techniques served as a starting point for representing the underlying n-dimensional non-linear relationships between ion concentrations and electrode responses, however standard versions of these algorithms are based solely on training data and have no mechanism for incorporating a priori knowledge into the system. A novel extended neural network architecture was thus developed which combines expert system concepts with machine learning: the algorithm learns from training data pairs using the standard back-propagation method but also constrains the system using known chemical characteristics of the system (i.e., charge neutrality must hold and electrical conductivity must be related to the concentrations of ionic constituents).

Studying the Ocean using Automated Sensing Systems

Nutrients (N,P,Fe,Si) are key drivers of ocean ecosystems and can be the controlling factor in some systems (e.g., the highly productive and economically important Gulf of Alaska), however unlike sea surface temperature or salinity, these constituents have no possibility for measurement (or inference) from satellite products. In-situ methods for high spatial and/or temporal resolution datasets are needed.

With funding from the National Science Foundation, Dr. Mueller has developed a trace-metal clean sampler (initially for measurement of iron in the near-coastal zones) capable daily water sample collection over deployment periods of months. Physical size is minimized by using standard syringes (10mL) as sample collection containers, with online sample preservation ensuring quality measurements after completion of the multi-month deployment. Initial field deployments were conducted in 2017 in Puget Sound in cooperation with the ORCA Buoy network, following on two years of collaboration with the United States Geological Survey and University of Washington Department of Oceanography on this work.

Alternative approaches for sensor development for nitrate (N) sensing are also being pursued with funding from MIT SeaGrant (NOAA) – for aquaculture applications – and from the Schmidt Marine Technology Partners (SMTP) – for coastal water quality monitoring. These projects leverage novel multi-layer, multi-sensor printing methods (Electrohydrodynamic-Jet) combined with machine learning approaches extended from the freshwater applications described above with the goal of enabling high resolution sensing of ocean nutrients. These projects were funded in 2020 and currently underway.

Enabling Next-Generation Methods for Urban Infrastructure Management

Urban environments are a critical intersection of humans and the environment, wherein human settlements may have a significant footprint on the surrounding environment but also where environmental conditions may substantively affect the health or economic well being of the residents. Our lab is working on advanced sensing systems to facilitate automated, more refined controls of water infrastructure (wastewater, stormwater) as well as improved monitoring of air quality at spatial scales that are relevant for citizens and for decision or policy making.

Wastewaters: Wastewater treatment facilities take advantage of a number of microbial processes (e.g., removal of nutrients via denitrification or anammox) which reduces the need for addition of chemicals but instead requires careful management of the system at all times to maintain conditions conducive for target bacterial strains. In contrast to large centralized plants like Boston’s Deer Island, many smaller towns and cities, as well as large cities in non-US countries, rely upon small-to-moderately sized treatment plants located closer to the communities they serve; the microbial communities in these smaller systems are more sensitive to changes in inputs (e.g., nutrient content, toxins) than large plants, in addition to having fewer full-time staff. Further, new microbes have recently been discovered that can significantly improve wastewater treatment processes by reducing resource demands (carbon and energy inputs) while improving effluent quality. Successful deployment of these new strains in treatment facilities, however, requires tightly controlling conditions to ensure optimal growth of the desired strain and suppression of competitors. In a complex medium like waste waters, sensors experience interferences from the many chemical molecules that are present, substantially decreasing their “usability”. Through use of multi-sensor suites, combined with an understanding of the biological and chemical composition of the reactor, however, development of an online real-time measurement system is possible – the key to reliable online controls that can stabilize microbial populations at any scale and under varying temperature and inflow conditions. Our lab is working with Dr. Mari Winkler and her students at the University of Washington to validate novel sensor systems for use in their lab-scale next-generation waste water treatment reactors, with a focus on online measurement of nutrients and waste products. This project is currently funded by the DARPA BTO.

Stormwaters: Most large cities have in past decades been moving to a system of separated stormwater sewers, a critical innovation to prevent sewage overflow into urban water bodies during large storms. As a consequence, however, stormwaters now flow relatively directly from pavement, into gray infrastructure (piping), and into surface waters typically with little-to-no treatment. Because of the lack of filtration through soils, as would happen in a natural environment, and the interaction of these waters with urban surfaces, this runoff can contain elevated concentrations of nutrients (P, N), metals, particulates, and biological contaminants. In fact, a 2015 study by the EPA found that over 600,000 km of rivers and shorelines are impaired by nutrient pollution, over 30,000 km of which already have set permit limits regulating discharge of phosphorous (P) – the main culprit of eutrophication (nutrient pollution) in fresh urban water bodies. Our lab is working on instrumentation that can enable cities to better understand patterns and amounts of nutrient discharge as well as develop solutions (e.g., controllers for selective diversion for treatment in constructed wetlands or water treatment plants) for reduction of nutrient discharge to meet set permit limits.

Urban Air Quality: Urban air quality is well known to be a driver of health of urban residents, with air pollution impacts of vehicles estimated to cause more deaths annually than vehicle accidents, yet available instrumentation for measurement of critical air pollution parameters remains costly and therefore it is typical that large cities have only a few monitoring stations (EPA or state DEP). However what data exist show that the heterogeneity of air quality has spatial variability on scales of blocks (<1 km), with worse air quality often found in lower income neighborhoods. There is a dire need for improved monitoring data to enable cities to implement responsive and targeted policies to improve air quality for all citizens. This lab is developing data analytic methods combining physics modeling with artificial intelligence/machine learning approaches to enable use of lower cost sensors for urban air quality monitoring – in a way that provides trustworthy and actionable data products for citizens and city managers.